Results 701 to 709 of 709

-

09-02-2023 #701

Registered User

Registered User

- Join Date

- Jun 2018

- Location

- SW Florida

- Posts

- 33

You might look for some marine grade hardware made from 316 stainless. That grade is less prone to corrosion than 304, and holds up well in the marine environment.

-

09-07-2023 #702

Thanks Bob. I donít think I need the utmost corrosion resistance but just stainless under the black coating will hopefully do. Iíve been spraying one of the screws I got with water or soap and water as a test and so far so good. No rust to be found. Hopefully these are just what I needed

Steve

1968 Dodge Charger All Wheel Drive project Red Bull<script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/5cce6da5/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script>

-

09-25-2023 #703

Red Bull 1968 Charger AWD Hemi 6 speed

Got the reverse lock out mechanism wrapped up and in place. So far really happy as it positively stops me from going into the reverse gate and puts me right into 5th.

With that wrapped up, I had no excuses to not road test the car again. SoÖ. A show just so happened to be going on this past weekend about 20 miles from my house. Signed up and as anxious as I can get, headed out for it with a neighbor following just in case. Did have one moment Iíll get to, but we actually made it! The drive home was uneventful as well and it was interesting to actually begin assessing how the car actually is as a car.

Initial assessment from me is that I really like just how tight the car feels. Every suspension mount is a bearing or rod end so there is no play in any piece. The steering feels so good and no unwanted movement anywhere. I was mostly on smooth pavement so canít yet say how much Iíll hate it on rough stuff though. Overall just very happy with how is acting at the moment.

Now, on to the issues:

1- the engine shut down once as I was coasting to a stop at a light. I think I know the cause so not yet worried about that one. The big issue is I believe Iím heat soaking my starter. Itís very close to the headers I built. The headers were ceramic coated and I wrapped them with DEI header wrap to attempt to stop this. I think Iíll get their starter blanket as well. The issue is that once I was stalled, the starter barely wants to crank. When I try, it turns the engine over very slowly. Just one compression cycle at a time. When I held down the starter button for a few seconds that ended up blowing my 250 amp mega fuse I have right after the battery.

I was able to get started again by hooking my a jumper pack to my battery. That helped it crank up just a little bit faster and did the trick. But still, with that extra juice it wasnít cranking as fast as it normally does.

Also worth mentioning that once I got home after the 30-ish minute drive I shut it down normally. Then just to test it I tried to start it again. Did the same thing where the engine would just crank over one cycle at a time.

To go over the battery circuit, I used a battery relocation kit and am using their 2ga wire from the battery to that mega fuse maybe a foot away. Then the wire goes along the frame rail and to the starter. Then a wire from that same starter stud going out to the rest of the car. The ground wire is 2ga as well and about a foot long just going to a stud welded to the rear passenger side frame rail. All ends of these wires have good quality copper terminals crimped on with a hydraulic crimper. Just saying I donít think itís anything to do with the electrical system.

So what can I do to fix the heat soak on the starter? Maybe a remote solenoid? Iíll running a quick time bell housing and that uses a stock 2010-ish hemi challenger starter. If needed, I could hack off the solenoid and just run a wire to it instead. I really donít have any room to move around the exhaust or front driveshaft.

2- Iím running a hydraulic switch to activate my brake lights. The relay is close enough I can hear it click. Issue is with my manual brakes I really donít have to push hard to just barely start to slow down if Iím coasting to a stop. So unless I push the brakes harder, the lights donít actually come on. The brake pedal is a floor mounted tilton triple master assembly. What other options are there that would be more sensitive to when Iím just barely braking? Iím envisioning something like a plunger style factory brake light switch that will activate the moment I just barely touch the pedal.Steve

1968 Dodge Charger All Wheel Drive project Red Bull<script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/5cce6da5/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script>

-

09-25-2023 #704

Maybe try a heavier cable. 2 gauge seems a little small. I use the cable from 5th gen Camaros that I buy on eBay. It’s 00 if I remember right. High quality cable.

https://www.ebay.com/itm/26633597649...Bk9SR6bytubZYg1969 Camaro - LSA 6L90E AME sub/IRS

1957 Buick Estate Wagon

1959 El Camino - Ironworks frame

1956 Cameo - full C5 suspension/drivetrain

1959 Apache Fleetside

-

09-25-2023 #705

This is the kit I used. Trusted that if they sold it like this, itís good enough

Check out this page from Summit Racing https://www.summitracing.com/parts/tay-48000Steve

1968 Dodge Charger All Wheel Drive project Red Bull<script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/5cce6da5/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script>

-

09-25-2023 #706

Good idea about grabbing oem stuff. I always trust and like to adapt factory parts when possible.

Something I read a while ago was that wires are able to carry more current the warmer they get. Or at least their resistance drops as temps increase. Please correct me if Iím wrong. The wires are routed away from heat as best I can. Also I started the engine about ten times with no issues a few days ago as I was changing the gauges on my digital dash. All times it started just fine but was only running for a few seconds to see what the gauges were showing.Steve

1968 Dodge Charger All Wheel Drive project Red Bull<script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/5cce6da5/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script>

-

09-26-2023 #707

Resistance increases as it heats up. So the voltage drop across the cable increases as the cable gets hotter.

Don1969 Camaro - LSA 6L90E AME sub/IRS

1957 Buick Estate Wagon

1959 El Camino - Ironworks frame

1956 Cameo - full C5 suspension/drivetrain

1959 Apache Fleetside

-

10-25-2023 #708

Red Bull 1968 Charger AWD Hemi 6 speed

With the weather cooling down around here Iíve been slow to get at the car but did take a look at the battery cables. There was a good 3 inches of air space between the ceramic coated and wrapped headers and the battery cables. Obviously not enough so Iím doing what I can. I was able to move the cables away a bit more and also wrapped with DEI titanium spark plug wrap. Havenít tested that yet but hope to soon.

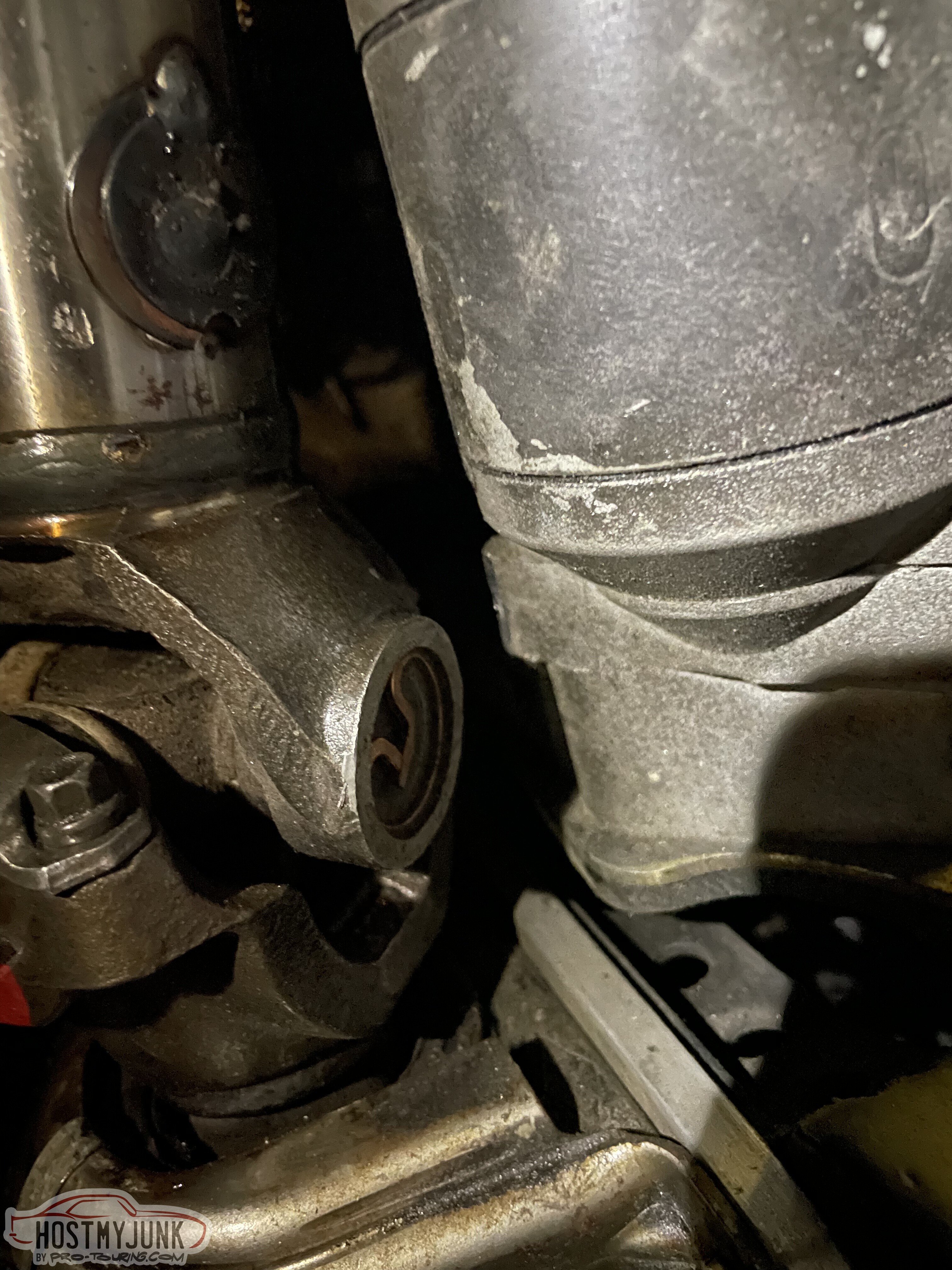

Looks closer that they really are here. The cable from the bottom left is from the battery. The other ones goes from there are powers the rest of the car. Never had an issue so far with voltage anywhere but the starter.

Another issue I heard was a knocking noise coming from around the front driveshaft when taking off from a stop. Figured that was when the driveshaft was under a bit of load. I had a concern that might happen as the center carrier is held in place by two rubber bushings. I could hit the driveshaft yokes into other things just by pushing on em. Didnít know if it would happen under load but turns out it does. It goes in towards the center and makes contact with the starter. There was about 3/4 inch between them just sitting, but that was my noise under load.

Again, pictures donít to it justice but there is a small witness mark on the starter. To address this I did two things. It had a 3/8 thick aluminum spacer on the mount to move the carrier bearings out. That got changed to 3/4. Other thing was to fill in the slots in the rubber bushings. All those holes really allowed all the movement to occur. I just squirted RTV in there so fill it in. Iíll have to see how long itíll last for. If the experiment fails, I figure Iíll have to cast new bushings with a firmer material.

Steve

Steve

1968 Dodge Charger All Wheel Drive project Red Bull<script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/5cce6da5/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script><script type="text/javascript" src="safari-extension://com.ebay.safari.myebaymanager-QYHMMGCMJR/85dc54c0/background/helpers/prefilterHelper.js"></script>

-

10-30-2023 #709

Nice fixes!

1955 Nomad project LC9, 4L80e, C5 brakes, Vision wheels

1968 Camaro 6.2 w/ LSA, TR6060-Magnum hybrid and etc SOLD

1976 T/A LS1 6 Speed, and etc. SOLD

Follow me on Instagram: ryeguy2006a

-

Reply With Quote

Reply With Quote